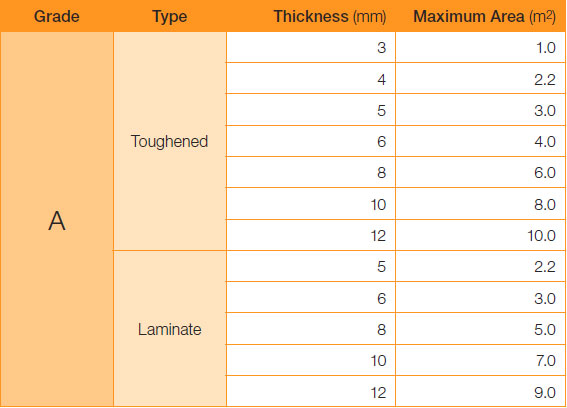

AS1288-2006 Table 5.1 – Maximum Areas of Safety Glass*

AS1288-2006 Table 5.1 – Maximum Areas of Safety Glass*

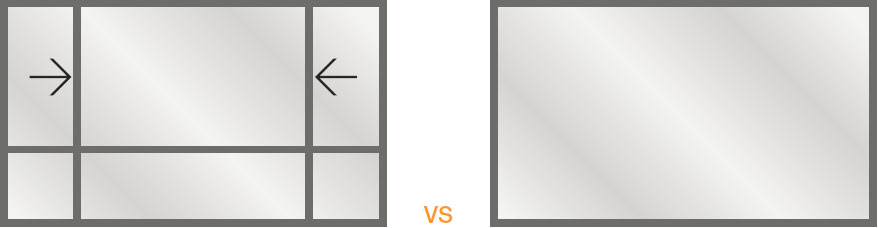

Standard size SFS/FFF 2100mm x 3000mm VS Single ‘F’ Fixed Lite of equivalent size

Standard size SFS/FFF 2100mm x 3000mm VS Single ‘F’ Fixed Lite of equivalent size

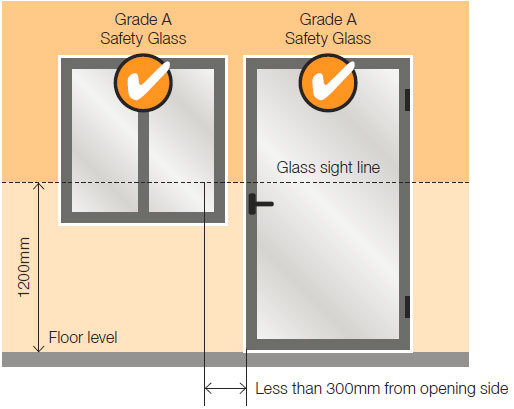

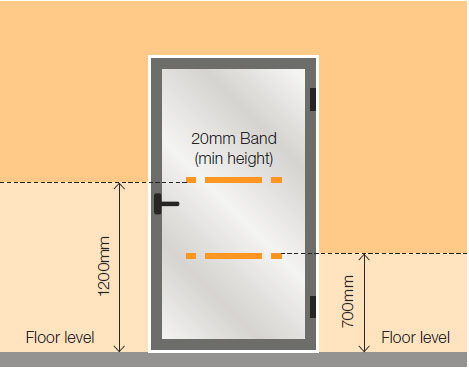

Example - Hinged Doors

Example - Hinged Doors

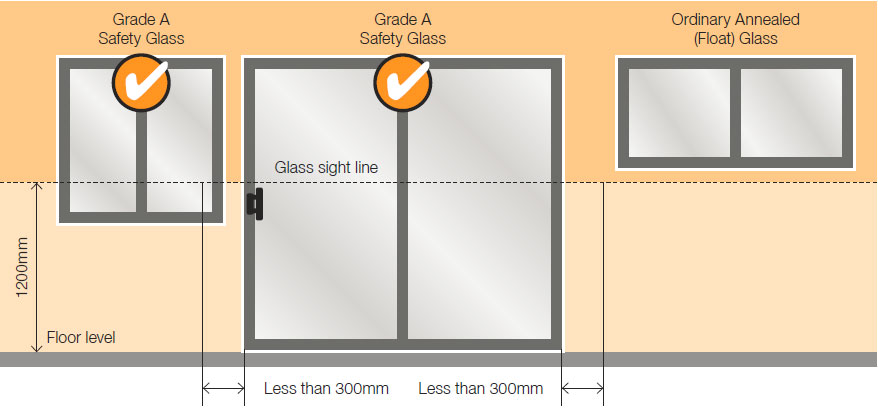

Example - Sliding Doors

Example - Sliding Doors

Example - Doors

Example - Doors

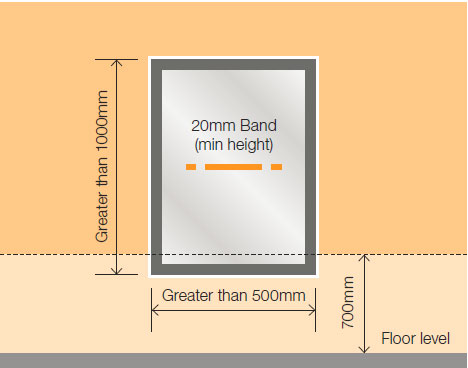

Example - Any Glazing

Example - Any Glazing

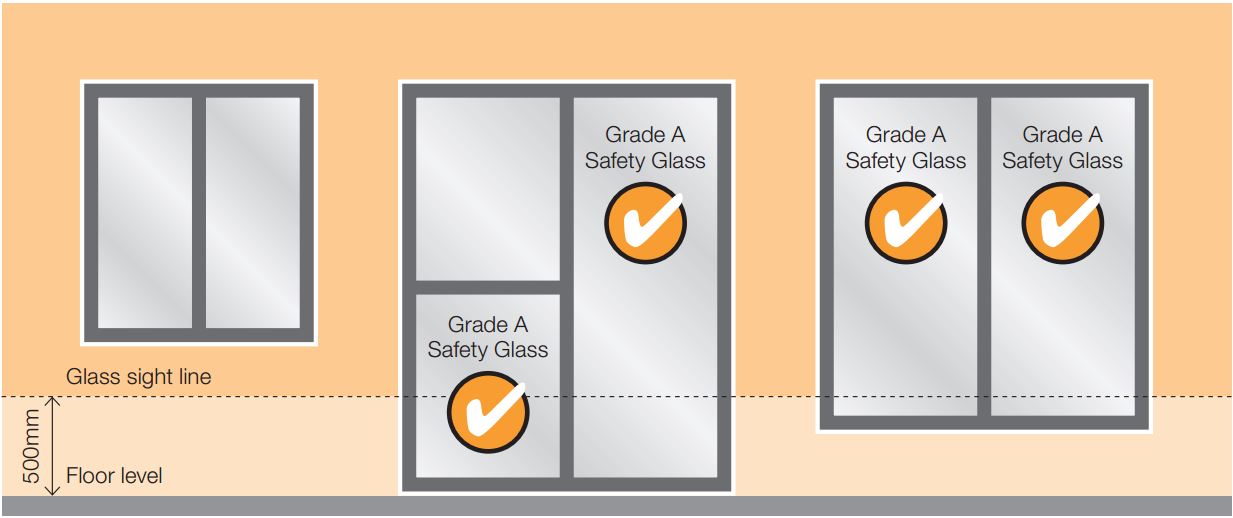

Example - Grade A Safety Glass Required

Example - Grade A Safety Glass Required

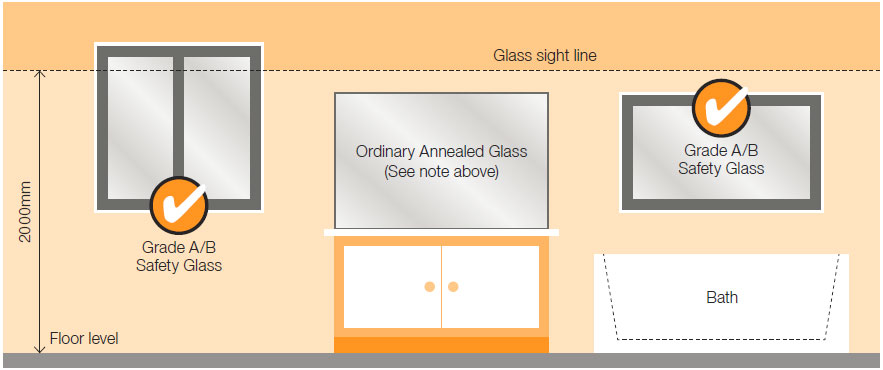

Example - Bathroom

Example - Bathroom

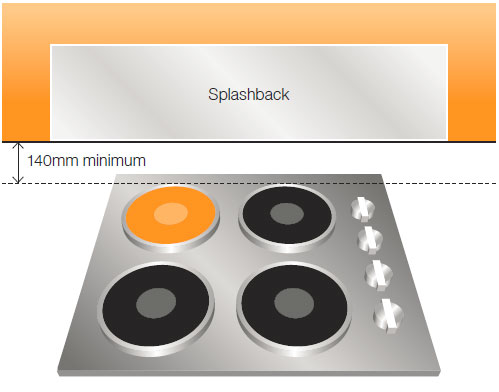

Example - Splashback

Example - Splashback

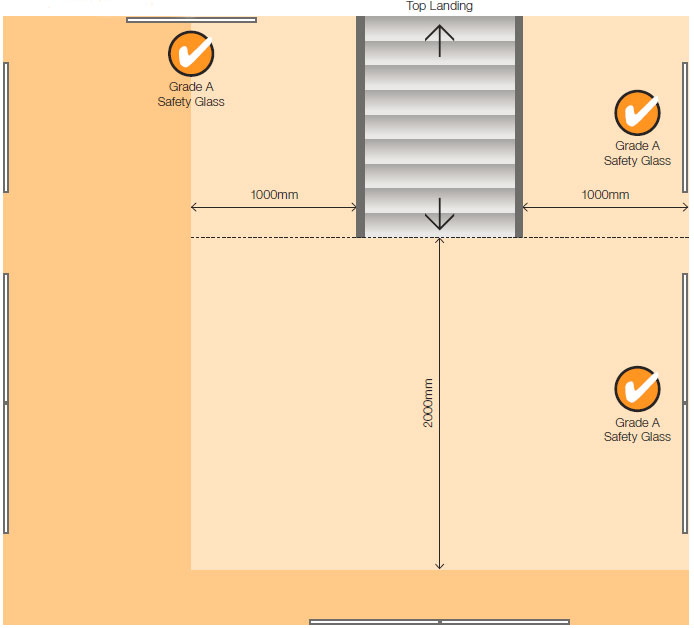

Example - Stairway

Example - Stairway

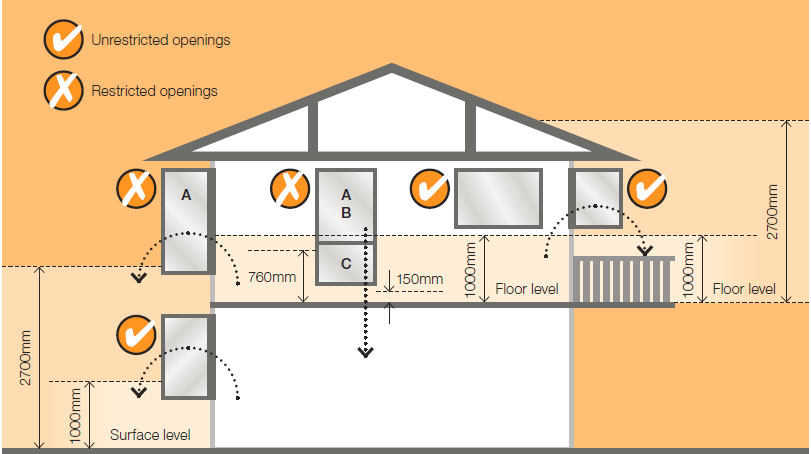

Example - Restricted Openings

Example - Restricted Openings

2012 - 2024 © Dazmark Windows. ALL Rights Reserved. Privacy Policy